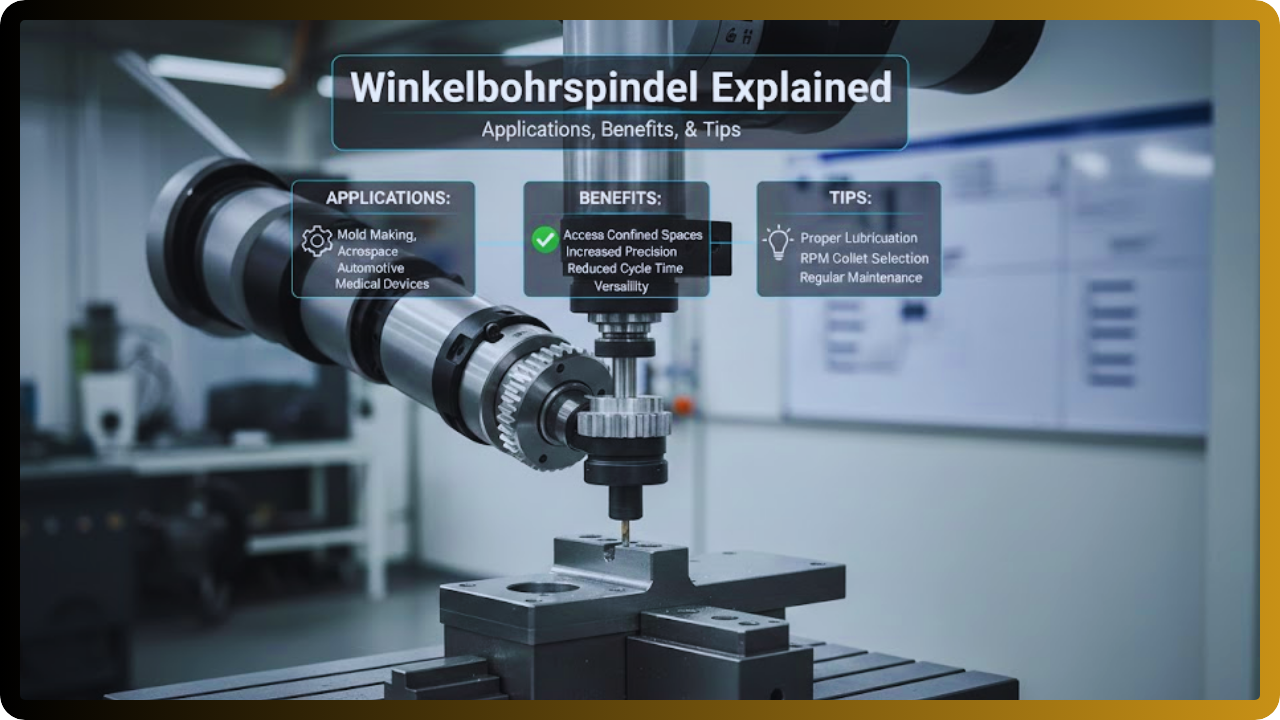

Precision machining often requires tools that can reach difficult angles without compromising accuracy in complex production environments. Manufacturers constantly seek ways to reduce setup time while maintaining consistent quality. Advanced attachments help achieve these goals by enabling multi-angle operations. These solutions support efficient workflows and improved dimensional control. Understanding the role of a winkelbohrspindel is essential for modern CNC and milling applications. Using the tool correctly improves productivity and reduces errors across all machining tasks, making it an indispensable component for precision manufacturing.

Who Is a Winkelbohrspindel?

A winkelbohrspindel is a precision-engineered attachment designed for angled drilling and milling operations. It redirects rotational motion from the main spindle to a different axis, allowing machining on side faces without repositioning the workpiece. The tool is commonly used in CNC machining centers and milling machines. Its design focuses on accuracy, rigidity, and durability. Regular use in the proper setting maximizes both efficiency and surface finish quality. This attachment is especially valuable in environments where consistent precision and repeatability are required.

Purpose of Angular Machining Tools

Role in Modern Manufacturing

Angular machining tools expand the functional capabilities of standard machine tools. They allow complex features to be machined in a single setup, reducing alignment errors and improving production efficiency. Manufacturers benefit from faster cycle times and more consistent results. The winkelbohrspindel plays a central role in achieving these advantages. It streamlines workflow and reduces unnecessary machine downtime. Its integration into production lines improves overall operational flexibility and output quality.

Working Principle of the System

Mechanical Power Redirection

Angular attachments operate by redirecting rotational energy through precision gearing systems. Power is transferred smoothly while maintaining torque consistency. Sealed housings protect internal components from wear and contamination. Proper lubrication ensures smooth operation over extended periods. A winkelbohrspindel uses this mechanism to deliver reliable and accurate machining performance. Its efficient mechanical design ensures long-term durability and repeatable results for complex operations.

Fixed Configuration Design

Stability and Repeatability

Fixed-angle designs are ideal for operations where the machining angle remains constant. These configurations provide high rigidity and vibration control. Stable alignment improves surface finish and dimensional accuracy. Their simple mechanical structure reduces maintenance needs. A winkelbohrspindel with a fixed configuration supports continuous production reliability. This design is particularly suited for high-volume manufacturing where consistent precision is critical across all parts.

Adjustable Configuration Design

Flexibility in Machining Tasks

Adjustable designs allow operators to change machining angles as required. This flexibility supports prototype development and custom manufacturing. Precision locking mechanisms ensure stability after adjustment. These designs reduce the need for multiple specialized tools. A winkelbohrspindel with adjustable capability enhances machining versatility. Its adaptability makes it ideal for facilities producing both small batches and mixed-component production runs.

CNC Machining Applications

Single-Setup Efficiency

CNC machining environments benefit greatly from completing multiple operations in a single setup. Side drilling and angular milling can be performed without adding extra machine axes. This reduces cycle time and setup-related errors. Consistent tool positioning improves machining accuracy. A winkelbohrspindel enables efficient and precise CNC machining processes. Its application allows manufacturers to increase throughput without compromising quality or reliability.

Performance and Accuracy Benefits

Precision and Productivity Gains

Improved performance is a key advantage of angular machining solutions. Reduced setup time leads to faster production cycles. Stable cutting conditions enhance surface quality and extend tool life. Machine utilization increases without the need for additional equipment. The winkelbohrspindel contributes directly to improved productivity and accuracy. Operators benefit from greater control and consistent repeatable results throughout production.

Selection Considerations

Matching Tool and Machine

Choosing the right attachment requires careful evaluation of machine compatibility. Speed capability and torque transmission must align with machining demands. Proper mounting ensures stability and alignment. Cooling and lubrication systems affect durability and overall performance. Selecting the correct winkelbohrspindel ensures reliable long-term operation. A careful selection process minimizes errors and reduces unnecessary maintenance requirements.

Maintenance and Service Life

Regular maintenance is essential for consistent machining performance. Proper lubrication protects internal components from wear. Clean operating conditions reduce the risk of mechanical failure. Scheduled inspections help identify potential issues early. A winkelbohrspindel that is well maintained delivers a long service life. Preventive maintenance also reduces downtime, improves operational efficiency, and extends the overall lifespan of the machine.

Accuracy and Tolerance Control

Maintaining tight tolerances is critical in precision manufacturing. Stable tool alignment ensures consistent dimensional accuracy. Reduced vibration improves surface finish quality. Angular machining relies on precise positioning to maintain specifications. A winkelbohrspindel supports accurate tolerance management in complex operations. Its precision helps manufacturers achieve high-quality results on every part, even in complex geometries.

Impact on Production Efficiency

Production efficiency improves when setup changes are minimized. Completing multiple operations in one setup saves time and labor costs. Streamlined workflows lead to higher output and less wasted effort. Machine utilization increases with fewer interruptions. A winkelbohrspindel significantly enhances overall manufacturing efficiency. Its integration supports optimized machine and operator productivity while lowering operational costs.

Compatibility with Machine Interfaces

Proper compatibility ensures safe and stable operation. Matching interfaces prevent vibration, misalignment, and premature wear. Correct fitment simplifies installation and removal. Compatibility directly affects long-term reliability and operational safety. A winkelbohrspindel must align precisely with the machine interface. Ensuring proper compatibility protects both the machine and tooling components during intensive operations.

Heat Management During Machining

Heat control is important during extended machining operations. Excessive heat can compromise tool life and dimensional accuracy. Effective cooling systems maintain stable cutting conditions. Controlled temperatures improve surface finish quality. A winkelbohrspindel designed for heat management supports consistent results. Managing heat also reduces wear on both the tool and workpiece, ensuring longer operational life.

Role in Complex Component Manufacturing

Complex components often require machining from multiple angles. Traditional setups involve frequent repositioning, which increases time and alignment risks. Angular machining simplifies these challenges. A winkelbohrspindel enables efficient production of intricate geometries. It helps manufacturers achieve precise results faster and with fewer errors. Its flexibility is especially valuable for prototypes and multi-faceted components.

Contribution to Tool Life

Tool longevity directly impacts production cost and overall quality. Stable cutting conditions reduce stress on cutting edges. Reduced vibration improves cutting efficiency. Consistent engagement extends tool lifespan. A winkelbohrspindel contributes to better tool life management. By minimizing wear, it lowers tooling costs and improves overall manufacturing sustainability.

Future Relevance in Machining Technology

Manufacturing continues to evolve toward automation and flexibility. Multi-angle machining solutions are increasingly valuable. Reducing setups and maintaining precision are key production goals. Advanced attachments support future machining demands. A winkelbohrspindel will remain relevant in modern manufacturing systems. Its adaptability ensures compatibility with emerging production technologies and methods.

Installation and Setup Process

Correct installation ensures stable and accurate machining performance. Proper alignment prevents vibration and misalignment during operation. Following machine specifications improves safety and reliability. Careful setup protects internal components from premature wear. A winkelbohrspindel installed correctly delivers consistent results. Well-planned installation also improves overall production efficiency and reduces machine downtime.

Cost Efficiency and Long-Term Value

Manufacturing investments must provide long-term benefits. Reduced setup time lowers operational costs and improves throughput. Improved accuracy minimizes rework and scrap. Efficient tooling increases machine utilization. A winkelbohrspindel delivers strong long-term value for manufacturers. Its reliability and efficiency help justify the initial investment while maximizing ROI over many production cycles.

FAQs

What is the primary function of a winkelbohrspindel?

It enables angled machining without repositioning the workpiece, reducing setup errors and saving time.

Is a winkelbohrspindel suitable for CNC machines?

Yes, it integrates smoothly with CNC machining centers and supports complex operations.

Does a winkelbohrspindel improve machining accuracy?

Yes, it stabilizes alignment and reduces errors, ensuring consistent quality.

Can a winkelbohrspindel be used for milling and drilling?

Yes, it supports both operations, making it versatile for multiple machining tasks.

Is a winkelbohrspindel used in high-volume production?

Yes, fixed-angle configurations are common in repetitive manufacturing to maintain efficiency and precision.

- You May Like this:Esports Gaming EmbersLasVegas Las Vegas’s Premier Gaming Experience

Final Thoughts

A winkelbohrspindel is a critical tool for modern precision machining. It enables complex angled operations with high accuracy. Reduced setup time improves productivity and repeatability. Its adaptability supports both custom and large-scale manufacturing. Continued innovation ensures it remains relevant in advanced machining environments. Investing in this technology delivers long-term value for manufacturers. Additionally, proper selection, operation, and maintenance maximize efficiency, reduce costs, and improve the lifespan of both tools and machines. Understanding its full capabilities allows manufacturers to achieve the highest level of performance in any production setting.